![]() 1. Download PDF version of this Report or, 2. View this case study posted at BEIC website.

1. Download PDF version of this Report or, 2. View this case study posted at BEIC website.

GOAL

To cut lighting energy bills of fluorescent lighting in two rarely used emergency corridors by converting them to Smart dimmable LED light.

BEFOREFor safety reasons, the rarely used emergency escape corridors inside an industrial building located in Metro Vancouver, Canada are lighted round the clock and costs more than $700 per year in electric bill per corridor. Due to the short life span of fluorescent lamps, some of the lamps were already burnt out and a few others flickered annoyingly. After conversion to Smart LEDs with Alec SLC, huge energy savings are realized.

|  |

|

What installer says: “It was amazingly quick and easy to retrofit! It really helps that the controller can be preconfigured before installation and that the parts all stick on magnetically and firmly. Not having to remove the fixture or wire above the ceiling saved me a lot of time and disposal logistics headaches.” – Mark Kosloski of Dadsons Electric, Vancouver BC. |

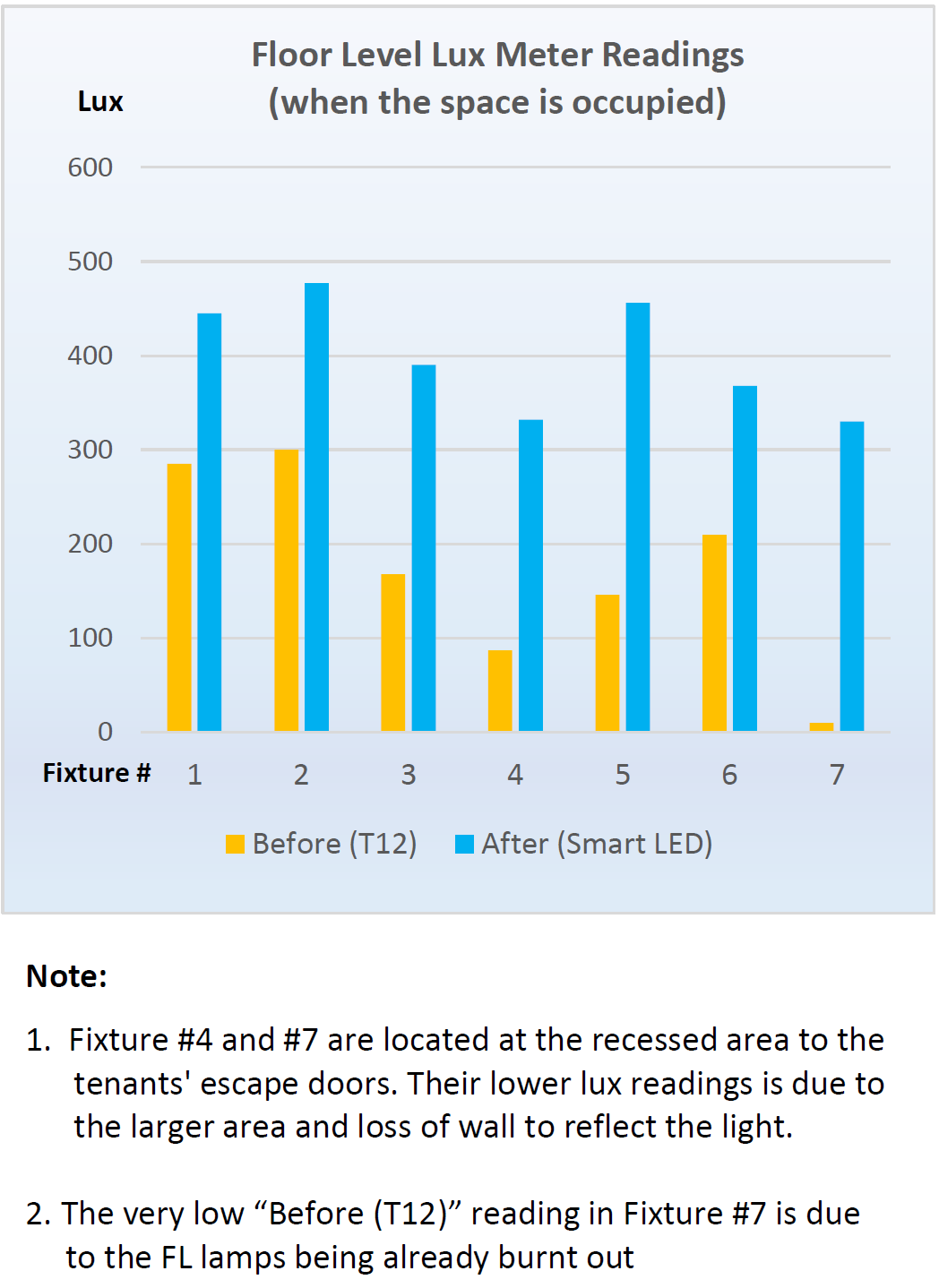

AFTERAll 7 fluorescent fixtures were converted to Smart LEDs using Alec SLC. Every fixture now stays in DIM mode when there is no occupant. When an occupant is detected by the occupancy sensor on each fixture, the corresponding light will brighten up immediately and smoothly to 80% brightness for up to 2 minutes. It then dims down to minimum brightness when no more occupant is sensed. Each light, when brightened is twice as bright as the original 2-tube T12 lighting. Thus, better and more energy efficient lighting is provided when required, after converting to Smart LEDs using Alec SLC. Watch video of a person walking down the converted corridor

|

|

|

What users say: “You and your company were very easy to work with. The proposal was detailed, the product works as advertised and the coordination and installation were smooth and effortless. Anytime I have a project for this type of lighting, I am coming to see you first.”– John Aveline (Property Manager, Bower Property Management Inc). “The savings are GREAT.” – Ben Roller (Strata Council Member) |

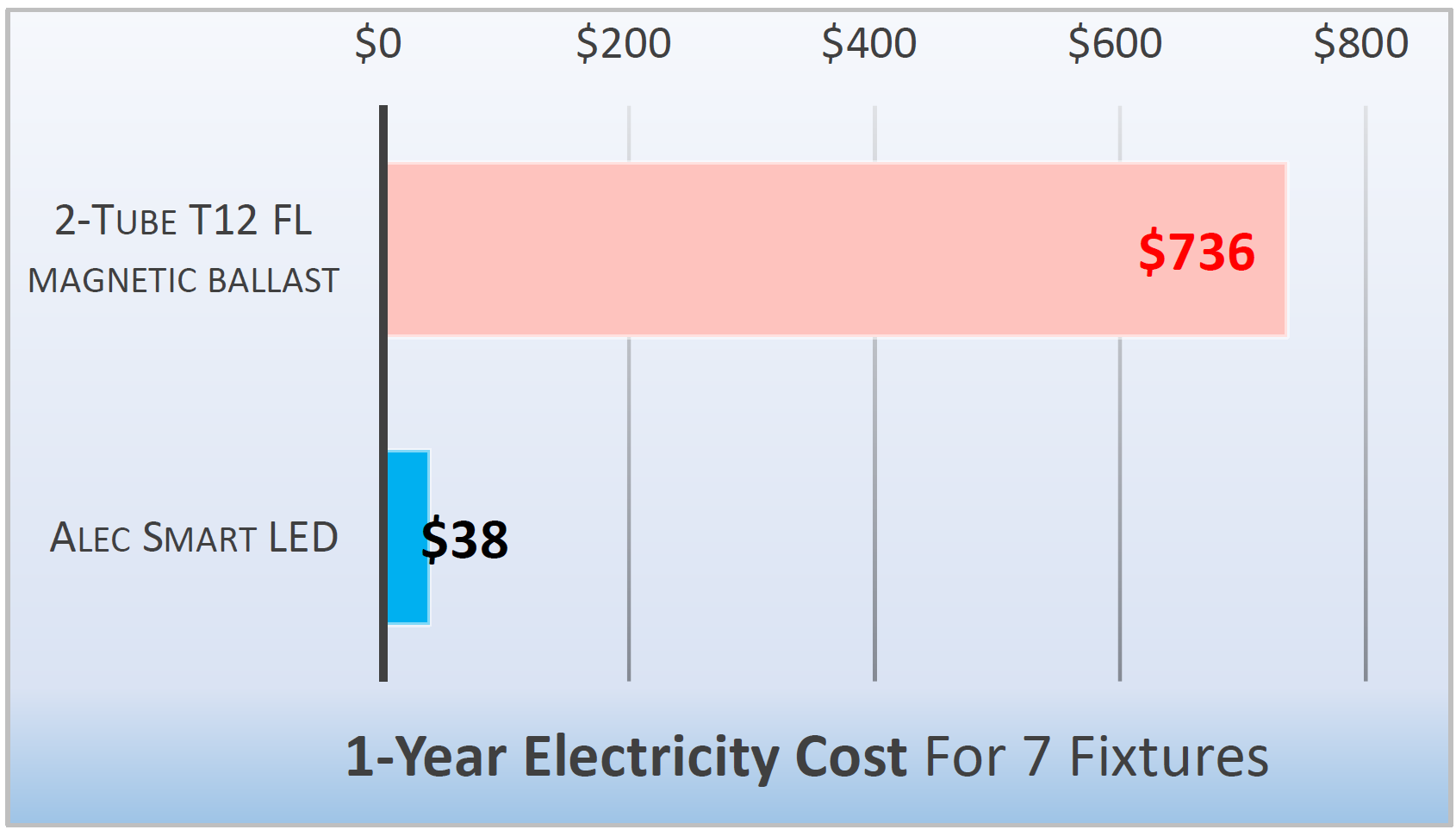

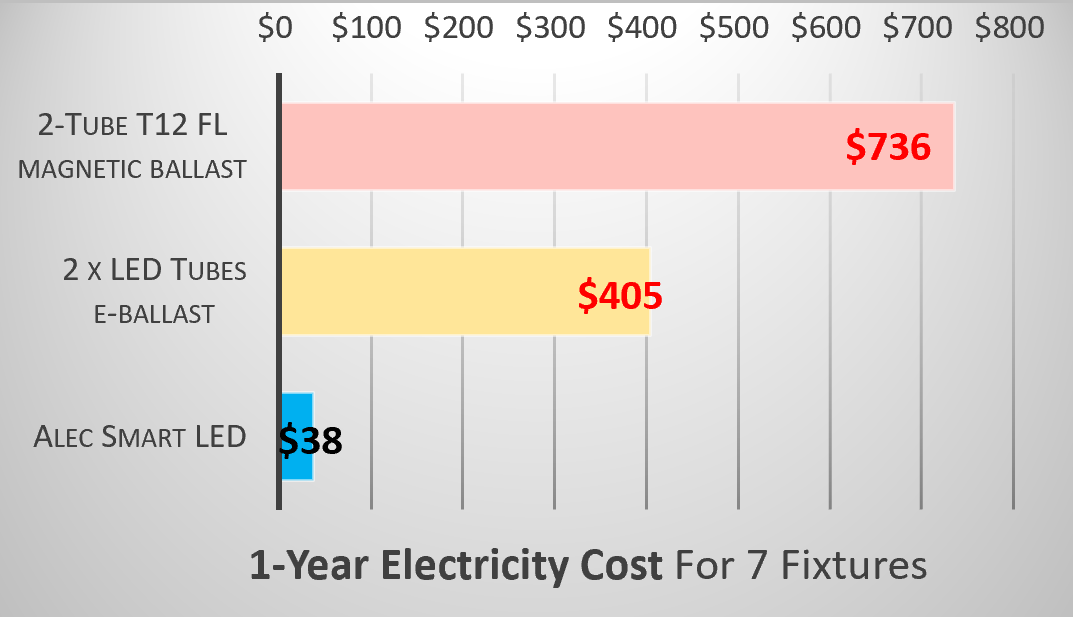

CONCLUSIONThe conversion of the 7 units of T12 fixtures to Smart LED Lighting cuts down energy usage substantially by 95% , and saves about $700 in electricity bill per year (based on $0.15/kWh). All lighting control settings are fully programmable, thus allowing the project to meet the most stringent energy codes such as ASHRAE 90.1-2016.  Conversion time of each fixture into Smart LED takes less than 10 minutes. The total conversion cost of this Emergency Corridor project was < $1000, including parts and labour, but before any utility rebates. Payback is < 1.5 years, even without utility rebate. You will enjoy even greater savings if your local electricity rate is higher than the $0.15/kWh used in this calculation. Many other lighting spaces such as stairwells, parkades, corridors, public washrooms etc, would also enjoy equally impressive savings once converted using the Alec Smart LED Conversion kit. Contact info@aleccontrol.com or call 1-877-874-7527 today to request for more information. |

Alec Smart LEDs vs T8 LED Tubes

An alternative retrofit solution is to replace the fluorescent lamps with electronic ballast compatible, T8 LED tubes (a.k.a. Tubular LED or TLED). However, TLED tubes will not work with the old magnetic ballast in these fixtures. The magnetic ballast must be replaced by electronic ballast and the old lamp holders may need to be replaced or re-wired, which increase the installation time and labour cost. The power consumption of a fixture retrofitted with TLED is usually higher than the sum of the rated power of all the TLED tubes, after compensating for the ballast factor and adding in the ballast power loss. The current generation TLED thus provides less than 50% energy savings.

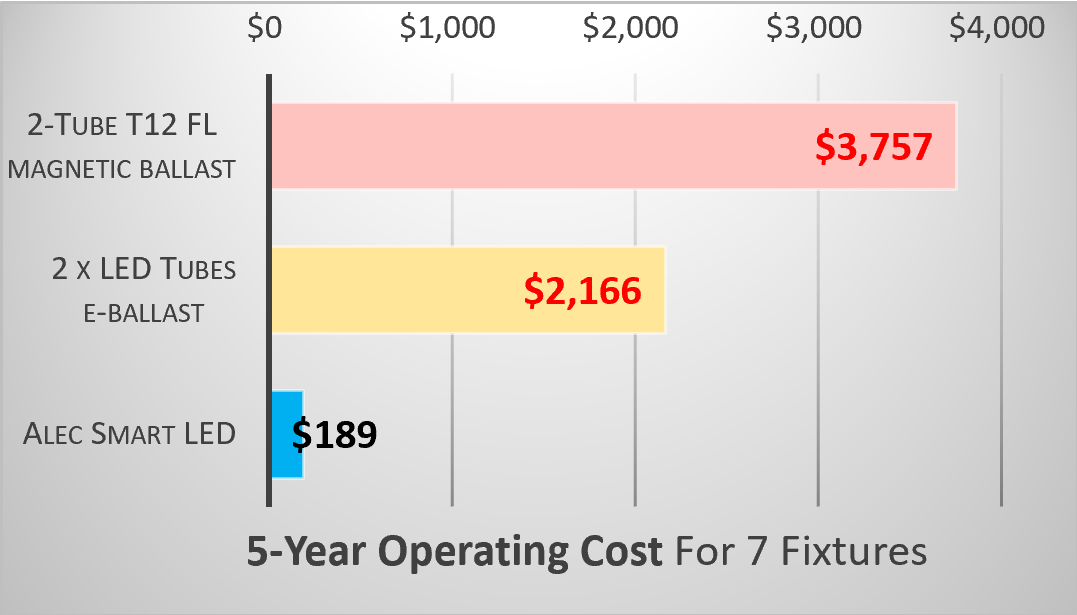

The following table and charts compare a T8 LED tube solution vs an Alec SLC solution. Without a doubt, the Alec SLC solution is indisputably superior to the T8 LED tube-replacement solution, in terms of cost savings. Your savings start immediately and even extend beyond the typical 5-year lifespan of a TLED tube, because the dimming feature of Alec SLC’s LEDs enable them to last much longer.

| T8 LED Tube | Alec Smart LEDs | |

| Energy Savings compared to T12 | Save only about 40~50% energy | Save up to 95% energy |

| Require ballast maintenance? | YES (every 15K to 25K hours) | NO |

| Lamps near end of life after 5 years? | YES | NO – Lights are still “lightly used” after 5 years due to dimming |

|

|